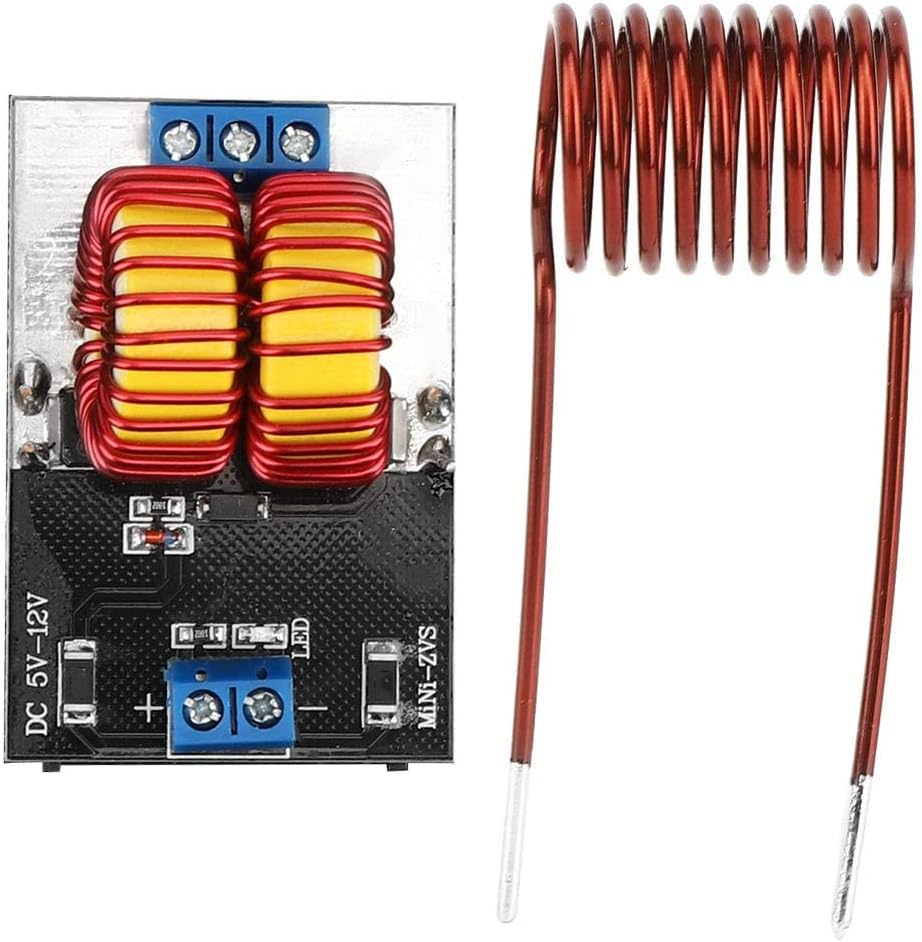

ماژول کوره القایی ZVS حداکثر توان 120وات

5-12V 120W Mini ZVS Induction Heating Board Flyback Driver Heater Ignition Coil

Product Details

• ZVS heating power supply module includes the heating coil

• Input Voltage:DC 5V~12V(This voltage range is the voltage during operation, not the voltage when the power supply is unloaded).

• Ensure all the components welding right, power line connected in the right way, then to set up an electric circuit.

• The width of the heated object is as far as possible between the 1/3~1/2 of the inner diameter of the heating coil, the maximum width is less than 2/3.

Description

5v-12 v ZVS induction heating power supply module tesla Jacob’s ladder + coil

1.the maximum power of 120W (12V induction heating) Push the ignition coil 12V, when the primary 5 + 5 turns, 30W or so.

2. the input voltage DC 5V ~ 12V (5V voltage exceeds 12V or lower than the seller is not guaranteed to work properly, the input voltage is not within this range, a problem the seller is not liable!)

3. Make sure that all components soldered correctly, the power line is not reversed negative, then power!

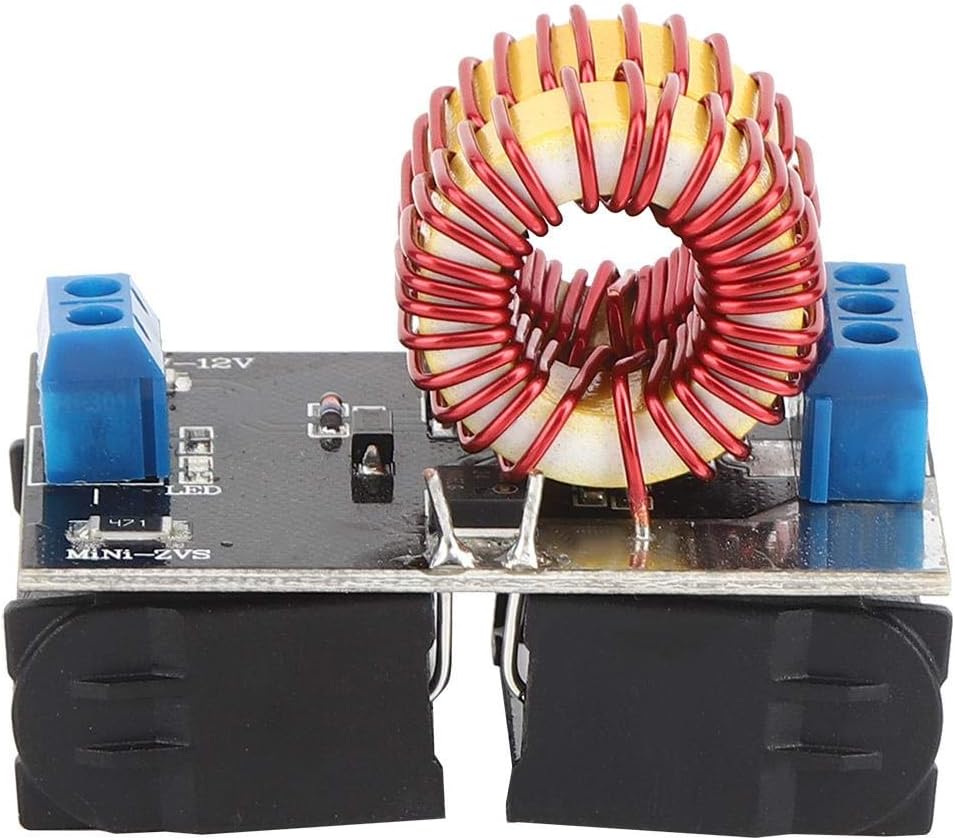

Size:56 x 37 x 16mm

Package Included

1 x induction heating power supply module

1 x coil

Note

1.Mini version ZVS no tap finished product induction heating for Teslastepladder drive without cooling fan.

2.This heating plate requires a certain amount of hands-on ability and related knowledge.

3.The maximum power of 120W (12V induction heating).Push the high voltage package 12V, when the primary 10 turns, about 30W.

4.The input voltage DC 5V ~ 12V, this voltage range is the voltage at work, not the voltage when the power supply is empty!

5.Confirm that all components are soldered correctly, the positive and negative poles of the power cord are not reversed, after the load is connected (heating coil, high voltage package), and then power on! No load can be powered! No-load power is easily damaged!

6.PCS heating coilThe width of the heated object should be between 1/3 and 1/2 of the inner diameter of the heating coil, and the maximum should not exceed 2/3!

The diameter of the heated object should be controlled within 20mm as much as possible.

If the heating is too large, it will be difficult to heat up to red. After all, the power is limited.

Inductive heating, usually work for 5 minutes to power off cooling.

Because the current is relatively large during induction heating, the coil heat is also relatively large.

When heated, part of the heat generated by the heated object is transmitted to the heating coil.

For a long time, the temperature of the heating coil is high.

If the heating coil is connected to the terminal, the plastic part of the terminal will melt! Therefore, it is best to solder the heating coil directly to the PCB during induction heating.

Please pay attention to this point.Long-term use is recommended to use copper tubes for coils and water cooling

دیدگاهها

هیچ دیدگاهی برای این محصول نوشته نشده است.